Sadee World Pvt. Ltd.

61 Jawahar Marg, Udhyog Parisar, 1st Floor, Sanjay Setu Sqaure, Indore 452007 (M.P.), INDIA

1) WAC-99: A highly concentrated latex emulsion for waterproofing applications as well as protective coating to cementations substances. WAC-99 is mixed with water & cement in 1:1:2.5 by wt. It is highly economical comparatively to any such product available in the market. (2) QCS-99: Ready to use. Seal immediately on contact with water. Effective crack sealing in concrete & masonry surfaces. Can stop the leaking dripping water, until the final repairs are carried out. Hardens instantly under continuous wet conditions. (3) Fiber mash : To strengthen & for reinforcement purpose. It is highly resistant to weather and sunlight. It is an elastomeric mash ,forms a very tough bond with subtract having good permeability rating. Resistant to high alkali, mild acids, sulphates salts, carbon dioxide. (4) Leakprime-99 : Aquaprime – 99 TM plays major role in facade coating system . It forms a dry water repellent zone beneath the coating consolidate the substrate and enhance bonding of the coating . It is gas permeable, durable, protects paints & plasters against harmful influences form within the masonry . (5) Leaksil-99 : Drastic Reduction in masonry maintenance cost with long term improved resistance to vagaries of weather. Protects Building , saves energy, keeps Substrate dry reducing the thermal conductivity. A water dilutable solution designed to impart repellency to masonry surface. (6) PSS-99: Forms a tough elastic rubber like seal. Accommodates continuous and pronounced cycle movement. High resistance to aging influences, physical damage and climate extremes. Good adhesion to most buildings materials. Resistant to temperature UV rays, ozone and weather conditions. Has a movement capability of +25% width joints. (7)HPC-99: It is a matchless heat proof compound which wonderfully works on masonry surface. It stops heat penetration and keeps cool by reflecting more than 90% heat of the sun from surface. It makes you comfortable to walk on, to live with and to save electric energy. It keeps water cool in any (8) TR.WPC-99: A boon for modern living. An amazing, powerful chemical to stop water leakage and dampness from cement concrete structure. High resistance to water, High mechanical strength, High scrub and impact resistance.

Rate : Rs. 70 per sq ft. Depends upon the condition of the terrace. ( Eligible rate is 10 Rs per coat) (Rates are inclusive of Chemicals, mechanical tools & Supervision etc…Cement will be provided by you.)

Basement underground waterproofing is one of the most crucial steps in maintaining a dry, healthy, and structurally sound home. Whether you're dealing with occasional dampness, persistent leaks, or full-blown flooding, waterproofing your basement can prevent long-term damage, mold growth, and costly repairs.

Underground basements are highly susceptible to water intrusion due to their location below ground level. Heavy rain, poor drainage, hydrostatic pressure, and foundation cracks can all allow water to seep in. Without proper waterproofing, this moisture can:

You may need basement waterproofing if you notice any of the following:

Interior solutions manage water that has already entered your basement. These include:

This is the most effective and long-lasting solution, involving:

Foundation cracks can be sealed using:

Hiring experienced professionals ensures the job is done thoroughly and safely. Benefits include:

Don’t wait until water damage becomes a serious problem. Basement underground waterproofing is a smart investment that protects your home, your belongings, and your family’s health. Whether you need a full exterior waterproofing system or simple crack repairs, getting the right solution starts with a professional inspection.

Underground water tanks play a vital role in storing water for domestic, commercial, and industrial use. However, without proper waterproofing, these tanks are vulnerable to water leakage, contamination, and structural damage. Underground water tank waterproofing is essential to ensure the durability, hygiene, and integrity of the water storage system.

Waterproofing an underground tank isn’t just about preventing water from leaking out—it also protects the structure from groundwater seepage, chemical erosion, and microbial growth that can affect water quality.

Here’s why waterproofing is critical:

Understanding the root causes of leakage helps in choosing the right waterproofing solution:

A widely used method that involves applying a cement-based slurry on the tank surface. Suitable for both new and old tanks. Non-toxic and safe for potable (drinking) water storage.

A chemical treatment that reacts with moisture in concrete to form insoluble crystals. Seals micro-cracks and capillaries internally. Ideal for long-term protection against water ingress and leakage.

These form a tough, durable, and chemical-resistant membrane. Polyurethane coatings are flexible and can accommodate structural movement. Epoxy is best for industrial tanks where chemical resistance is critical.

Bitumen-based waterproofing provides a flexible, protective barrier. Commonly used on the external surface of the tank to resist soil moisture and water pressure.

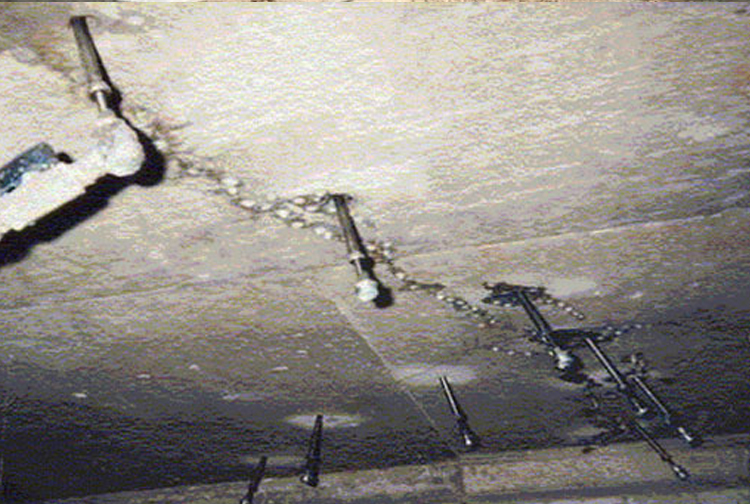

For tanks with existing leaks or cracks, pressure injection of PU or epoxy grout can seal and reinforce the structure. Effective for repairing localized damage without dismantling the tank.

Hiring a trained waterproofing contractor ensures:

Whether you’re building a new underground water tank or dealing with leaks in an existing one, professional waterproofing is a crucial investment. It not only protects the structure but ensures the water you store is clean, safe, and available when you need it most.

Overhead water tanks are essential for water storage in residential, commercial, and industrial buildings. But without proper waterproofing, these tanks can suffer from leakage, cracks, and contamination—leading to serious structural and health problems. Overhead water tank waterproofing is critical to ensure safe water storage and prevent costly repairs.

Water tanks are constantly exposed to water pressure from inside and environmental elements from outside. Over time, this leads to wear and tear that causes cracks and leakage. Waterproofing creates a protective barrier that ensures:

Here are the typical problems that arise in unprotected overhead tanks:

A common and cost-effective solution using a cement-based coating. Applied on the inner and outer surfaces of the tank. Non-toxic and safe for drinking water storage.

Highly flexible coatings that withstand temperature fluctuations and hairline cracks. UV-resistant, ideal for exposed overhead tanks. Forms a seamless, durable membrane.

Ideal for concrete or RCC tanks. Offers excellent flexibility and adhesion. Resistant to water, UV rays, and harsh weather conditions.

Two-component system ideal for tanks exposed to chemicals or requiring hygiene. Forms a hard, durable layer inside the tank. Non-porous and easy to clean.

Used to repair and seal existing cracks or leak points. Injection of resin under pressure to stop water penetration permanently.

Hiring an expert ensures:

Leaking overhead water tanks are not just a nuisance—they can damage your building structure, ruin interiors, and contaminate your water supply. With proper waterproofing, you can avoid these issues and ensure the safe, clean storage of water for years to come.

Swimming pools are a major investment, whether for residential, commercial, or recreational use. One of the most critical aspects of pool construction and maintenance is waterproofing—a process that ensures the pool remains watertight, prevents leaks, and enhances structural durability.

Without proper waterproofing, swimming pools are vulnerable to:

Waterproofing not only protects the pool shell but also ensures the longevity and performance of the entire pool system.

Bathrooms and washrooms are high-moisture areas that are highly susceptible to water leakage and dampness. Without proper waterproofing, water can seep into walls, floors, and ceilings, causing structural damage, mold growth, and unpleasant odors. Effective bathroom and washroom waterproofing ensures a safe, clean, and long-lasting space.

Water is constantly used in bathrooms and washrooms—from showers, sinks, taps, and toilets—which makes these areas vulnerable to leaks and dampness. Waterproofing these wet zones helps:

Applied as a liquid coating that forms a seamless, flexible membrane after drying. Suitable for floors, walls, and corners. Resistant to water and minor movements in the substrate.

A cement-based slurry applied to walls and floors. Easy to apply and cost-effective. Commonly used under tiles and in wet areas.

Pre-formed sheets made of bitumen, PVC, or rubber. Applied to surfaces before tiling. Provide durable and reliable waterproofing.

Highly elastic and durable. Suitable for complex areas and where flexibility is required. Excellent adhesion to concrete and other surfaces.

Used to seal joints, corners, and gaps between tiles and fixtures. Prevent water ingress in vulnerable points.

Terraces are exposed to harsh weather conditions such as rain, heat, and wind, making it essential to apply a durable finishing and waterproofing solution. A well-finished terrace not only enhances the aesthetic appeal of your home but also protects the underlying structure from water damage, cracks, and leaks.

Terrace finishing with cement, sand, and chips stone is a popular and effective method that combines the strength of cement and sand with the decorative and protective qualities of chips stone. This mixture creates a tough, non-slip surface that is resistant to wear and tear.

Terraces are constantly exposed to harsh weather elements such as rain, sunlight, and temperature fluctuations, making effective waterproofing essential to protect the structural integrity of the building. One of the most trusted and time-tested methods for terrace waterproofing is Brick Bat Coba.

Brick Bat Coba is a traditional waterproofing technique that involves laying broken bricks (brick bats) in a thick mortar layer on the terrace surface. This method provides a b, durable, and waterproof layer that protects the underlying concrete from water penetration and damage.